Linear guides are fundamental components in precision engineering, enabling smooth and accurate linear motion in a wide range of industrial and technological applications. These systems consist of a rail and a block or carriage, with internal rolling elements like balls or rollers that circulate to minimize friction and ensure consistent performance. Understanding their design, types, and uses is crucial for engineers, designers, and anyone involved in automation, robotics, or high-precision machinery.

What Are Linear Guides?

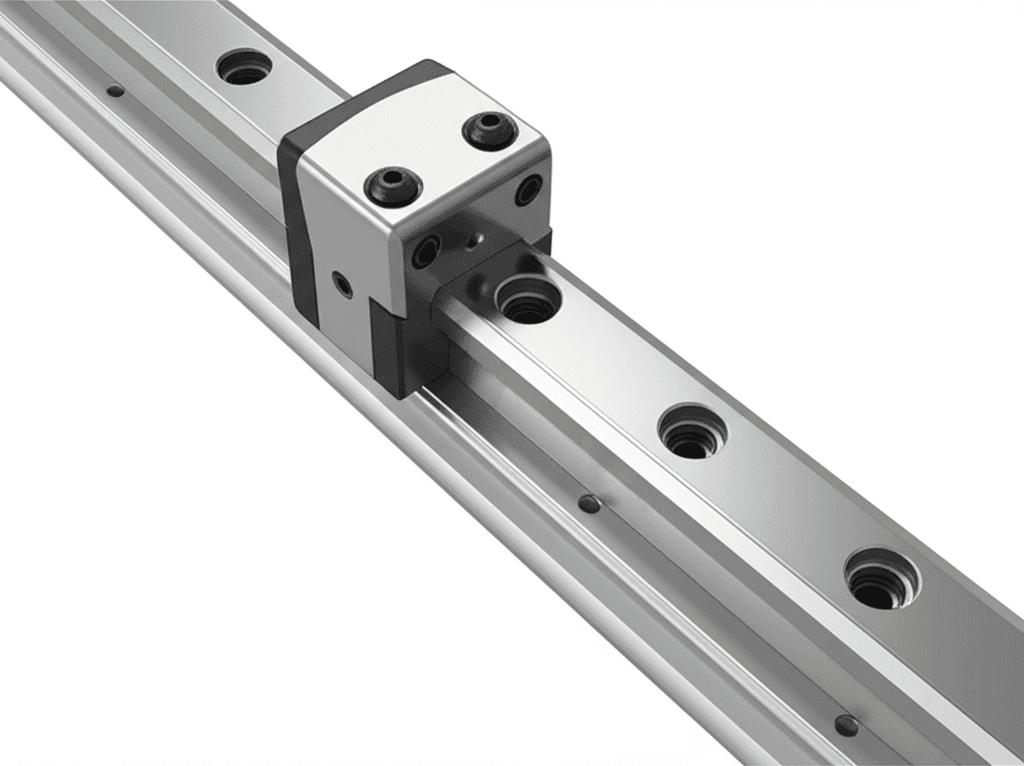

A linear guide is a mechanical assembly designed to facilitate precise linear movement along a fixed path. The core components include a hardened steel rail and a moving block that houses recirculating rolling elements. This design drastically reduces friction compared to traditional sliding mechanisms, resulting in higher efficiency, longer service life, and improved accuracy. Key advantages of linear guides include minimal deviation during operation, reduced energy consumption due to lower friction, and the ability to handle significant loads without compromising performance. These features make them indispensable in applications requiring repeatability and reliability.

Common Types of Linear Guides

Several types of linear guides are available, each suited to specific requirements based on load capacity, speed, environmental conditions, and space limitations.

Ball Type Linear Guides: These are the most widely used due to their efficiency, cost-effectiveness, and versatility. They employ ball bearings as rolling elements and are ideal for applications with moderate loads and high speeds.

Roller Type Linear Guides: Designed for heavier loads and higher rigidity, roller guides use cylindrical rollers instead of balls. They are commonly found in heavy-duty machinery, such as industrial presses and large-scale automation systems.

Miniature Linear Guides: Compact and precise, these guides are tailored for applications with space constraints, such as electronic assembly equipment, medical devices, and small-scale robotics. They offer high accuracy in a minimal footprint.

Selecting the right type depends on factors like operational environment, required precision, and mechanical constraints.

Applications of Linear Guides

Linear guides are integral to numerous industries and technologies, providing the foundation for precise motion control.

CNC Machines: In computer numerical control (CNC) equipment, linear guides ensure the cutting head or tool moves with micron-level accuracy, essential for manufacturing complex parts with tight tolerances.

Robotics: Robotic arms and automated systems rely on linear guides for smooth, reliable movement, enabling tasks like pick-and-place, welding, and assembly with high repeatability.

Medical Devices: Precision is critical in medical equipment, such as imaging systems, surgical robots, and diagnostic instruments. Linear guides facilitate accurate positioning and movement without vibration or backlash.

Semiconductor Manufacturing: The semiconductor industry demands ultra-clean and highly precise motion control for processes like wafer handling and lithography. Linear guides meet these requirements with minimal particulate generation and exceptional stability.

Additional applications include 3D printing, packaging machinery, automotive assembly lines, and aerospace systems, highlighting their versatility across sectors.

Benefits of Using Linear Guides

The adoption of linear guides offers several advantages over traditional sliding or friction-based systems.

Enhanced Accuracy: With minimal deviation and high repeatability, linear guides ensure consistent performance in precision-critical tasks.

Reduced Maintenance: The recirculating rolling elements distribute wear evenly, extending component life and reducing downtime for repairs or replacements.

Energy Efficiency: Lower friction translates to reduced power consumption, making systems more sustainable and cost-effective over time.

High Load Capacity: Modern linear guides can support substantial loads while maintaining smooth operation, suitable for both lightweight and heavy-duty applications.

Design Considerations for Linear Guides

When integrating linear guides into a system, several factors must be evaluated to ensure optimal performance.

Load and Speed Requirements: Determine the maximum load and operational speed to select a guide with appropriate capacity and durability.

Environmental Conditions: Consider factors like temperature, humidity, contamination, and exposure to chemicals or debris. Sealed or coated guides may be necessary for harsh environments.

Precision Needs: Applications requiring high accuracy may necessitate guides with preloaded rolling elements or enhanced stiffness characteristics.

Installation and Alignment: Proper mounting and alignment are critical to prevent premature wear and ensure smooth operation. Follow manufacturer guidelines for installation tolerances.

Maintenance Tips

To maximize the lifespan and performance of linear guides, regular maintenance is essential.

Lubrication: Use the recommended lubricant type and interval to reduce friction and prevent wear. Some guides feature automatic lubrication systems for convenience.

Cleaning: Keep guides free from dust, chips, and contaminants, especially in environments like machining or semiconductor fabrication.

Inspection: Periodically check for signs of wear, damage, or misalignment. Replace components as needed to maintain accuracy and reliability.

Future Trends in Linear Guide Technology

Advancements in materials, design, and smart technologies are shaping the future of linear guides. Innovations include the use of lightweight composites for reduced inertia, integrated sensors for real-time monitoring of load and condition, and developments in lubrication-free designs for maintenance-free operation. As industries increasingly adopt automation and IoT-enabled systems, linear guides will continue to evolve to meet higher demands for precision, efficiency, and connectivity.

In summary, linear guides are vital components that enable precision and reliability in modern engineering. By understanding their types, applications, and benefits, professionals can make informed decisions to enhance system performance across various industries.

Leave a Reply